Fresh Concrete On-Demand

Mix concrete on-site, so it’s always fresh and ready to use. No more worries about old, unusable batches.

Precise Mix Every Time

Make the right amount of concrete with the exact mix you need.

Flexibility

Easily switch mix designs without heading back to the plant, so you can tackle multiple jobs in one day without hassle.

Eliminate waste

Our trucks use less water to clean than barrel trucks. They also help use less fuel.

Control Your Budget

- Replace multiple ready-mix trucks with one volumetric mixer for cost savings.

- Skip delivery fees and keep concrete production in-house for better budget control.

- Track material usage and pouring in real-time with ACCU-POUR™ tools.

Control Your Environmental Impact

- Reduce waste by making only the concrete you need, saving resources and money.

- Use less water—just 8-10 gallons to clean a volumetric mixer versus 200 gallons for a barrel truck.

- Lower fuel consumption with fewer trucks needed, reducing your environmental footprint.

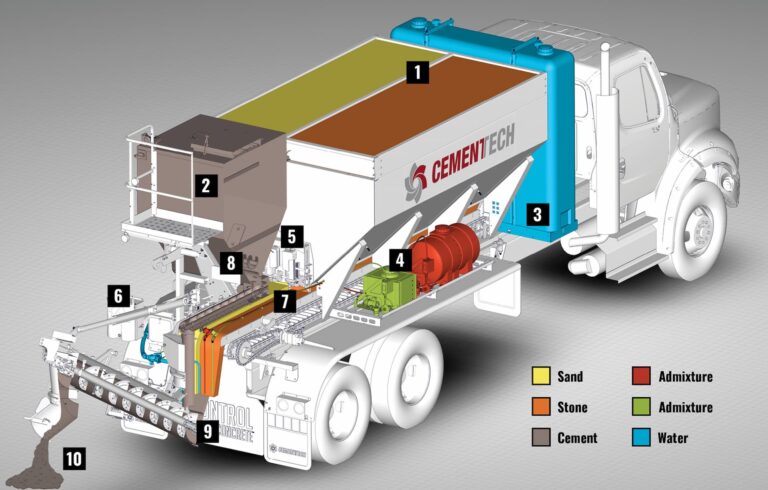

Volumetric Concrete Mixers vs. Traditional Barrel Mixers

Volumetric concrete technology is changing how we mix and deliver concrete, making it flexible for any project size. From their ability to customize mixes on-site to their efficient and cost-effective operation, volumetric mixers offer a level of flexibility and convenience that traditional methods can’t match.

Volumetric Mixer Manufacturers: Your Guide to Choosing the Right Mixer

Volumetric mixers provide on-demand concrete, reducing waste and improving efficiency. They allow businesses to take full control of their concrete production. Learn More >

Starting a Volumetric Concrete Business – Creating Opportunities to Lower Project Costs

Starting a volumetric concrete business can help customers overcome the scheduling challenges associated with concrete pours. Learn More >

Building a Greener Future: Sustainable Concrete Production with Volumetric Mixers

The construction industry is actively seeking more sustainable practices in concrete. Contractors are increasingly turning to innovative solutions like volumetric concrete mixers to reduce their environmental footprint. Learn More >

English

English Español

Español Français

Français