Building a Large Volumetric Fleet for Public Works and Parks

Building a Large Volumetric Fleet for Public Works and Parks

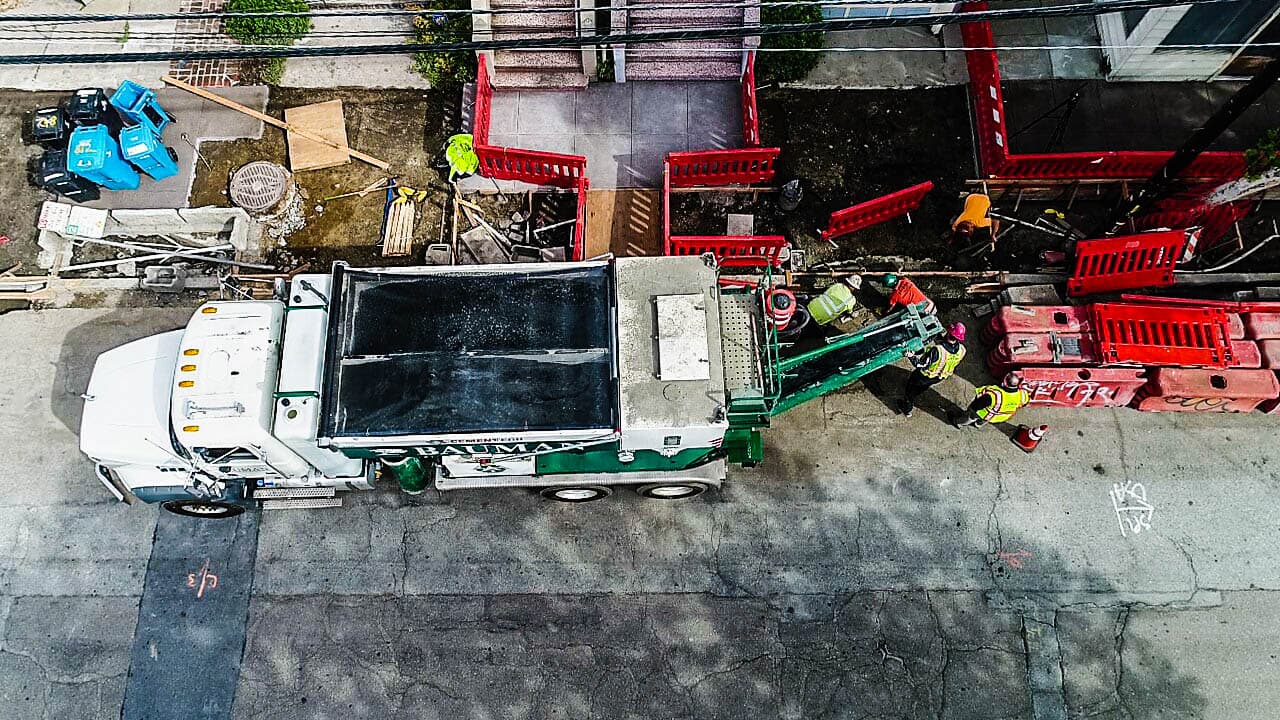

Since 1978, Bauman Landscape & Construction, Inc. has been a key player in San Francisco’s public works,

specializing in parks and streetscapes. Mike Bauman, the owner, and his daughter Angela, who helps run

the company, shared how their growing fleet of Cemen Tech C60 volumetric mixers has helped them

tackle concrete supply challenges and keep their projects running smoothly.

The Challenge: Unreliable Concrete Supply

Like many contractors, Bauman relied on traditional ready-mix concrete for years. But as San Francisco’s

construction demand surged, getting concrete delivered on time became a real struggle. “We started using volumetric mixers about six years ago because we couldn’t get concrete on time,” explains Mike Bauman. Not only were deliveries unpredictable, but prices for ready-mix were also skyrocketing.

Switching to Volumetric Mixers

After experiencing these issues with traditional suppliers, Bauman made the switch to volumetric mixers. “We were the first ones in the city to have a volumetric mixer,” Mike says. Initially, the City of San Francisco was hesitant to approve the use of volumetric mixers, but that changed after they saw the results on a major project.

“We used the volumetric mixers for about 2,000 to 3,000 yards of concrete onsite. After running tests, the results were phenomenal.”

A Green Approach: Recycling Concrete

One of the key advantages of the C60 mixers was their ability to use 100% recycled aggregate in the concrete mix. This was a major selling point for the City of San Francisco, which has strict recycling and sustainability requirements. Bauman’s mixers were not only able to meet these standards but exceeded them, helping to cement their reputation as a leader in green construction.

“The city loves it,” Mike says. “We take all the old concrete, crush it, and reuse it as aggregate in new concrete. It’s huge for them, and we’re the first in the city to use 100% recycled aggregate.”

Bauman’s recycling efforts not only reduce costs but also help them win jobs from contractors focused on earning LEED credits for sustainability. “It makes us more attractive to general contractors who need to meet green building requirements,” says Mike.

Operational Flexibility: Multiple Mix Designs, One Truck

With the ability to load multiple mix designs into the system, the team can easily switch between different types of concrete on the same truck . “We do a lot of streetscapes, and the ramps, curbs, and sidewalks all need different mixes. We used to need three short loads, but now we can change the mix three times in one truck and pour the entire job,” Mike explains. This has saved Bauman a ton of time and money.

Training and Support: Getting the Team Up to Speed

Transitioning to a new type of equipment can be tough, but Bauman’s team received hands-on training from Cemen Tech to get them up to speed. “Jim [Bishop] came out and trained our mechanics, drivers—everyone,” Mike recalls. This training has allowed Bauman’s team to operate the mixers efficiently and even train new drivers. “We can take someone with no concrete experience, like a UPS driver, and train them to run a C60.” The reliability

of Cemen Tech’s support and the ease of operating the C60 mixers have been crucial to the success of Bauman’s concrete operations.

Saving Time and Money with Volumetric Mixers

The C60 mixers also help Bauman save time by reducing downtime. “With our old brand of mixers, we were constantly repairing them. But with Cemen Tech’s mixers, there’s very little downtime. If something goes wrong, it’s usually the truck, not the mixer,” Mike says. The ability to produce concrete on-site also means Bauman can meet tight schedules and avoid delays. “We beat the schedule by almost a year on one streetscape project. The city was blown away,” Mike adds.

Expanding Capabilities: Gunite, Shotcrete, and More

Bauman’s volumetric fleet has also allowed them to diversify the types of concrete they offer. “We’ve started doing shotcrete, gunite, and slurry mixes, which are really popular around here,” Mike says. With the volumetric mixers, they can meet customer needs quickly without waiting weeks for specialized mixes from a plant.

By switching to Cemen Tech’s volumetric mixers, Bauman Landscape & Construction has not only solved their concrete supply problems but also gained flexibility, reduced costs, and expanded their business. “It’s been a game-changer for us,” Mike says. With the ability to produce high-quality, sustainable concrete on-site and the support from Cemen Tech, Bauman is well-positioned to continue their leadership in public works projects across San Francisco.

Sustainable Concrete Solutions with Bauman Landscape

Bauman Landscape & Construction switched to Cemen Tech C60 mixers to improve concrete supply, save costs, and meet sustainability goals with 100% recycled aggregate.

Company Profile: Bauman Landscaping

Location: San Francisco, California

Customer Segments: Landscape, Public Works, Concrete Delivery

Products: C60

Website: baumanland.com

How Bauman Landscape Solved Concrete Supply Issues

We were the first ones in the city to have a volumetric mixer. Initially, the City of San Francisco was hesitant to approve the use of volumetric mixers, but that changed after they saw the results on a major project. We used the volumetric mixers for about 2,000 to 3,000 yards of concrete on-site. After running tests, the results were phenomenal.

"*" indicates required fields

English

English Español

Español Français

Français