“We’re able to do multiple pours at one location with one truck. We can do 3,000 psi kicker, a 4,000 psi headwall, and then we can change that truck over and pour flowable fill out to cover a line up for them. That way they don’t have to have three trucks – we did it with one.”

C SERIES

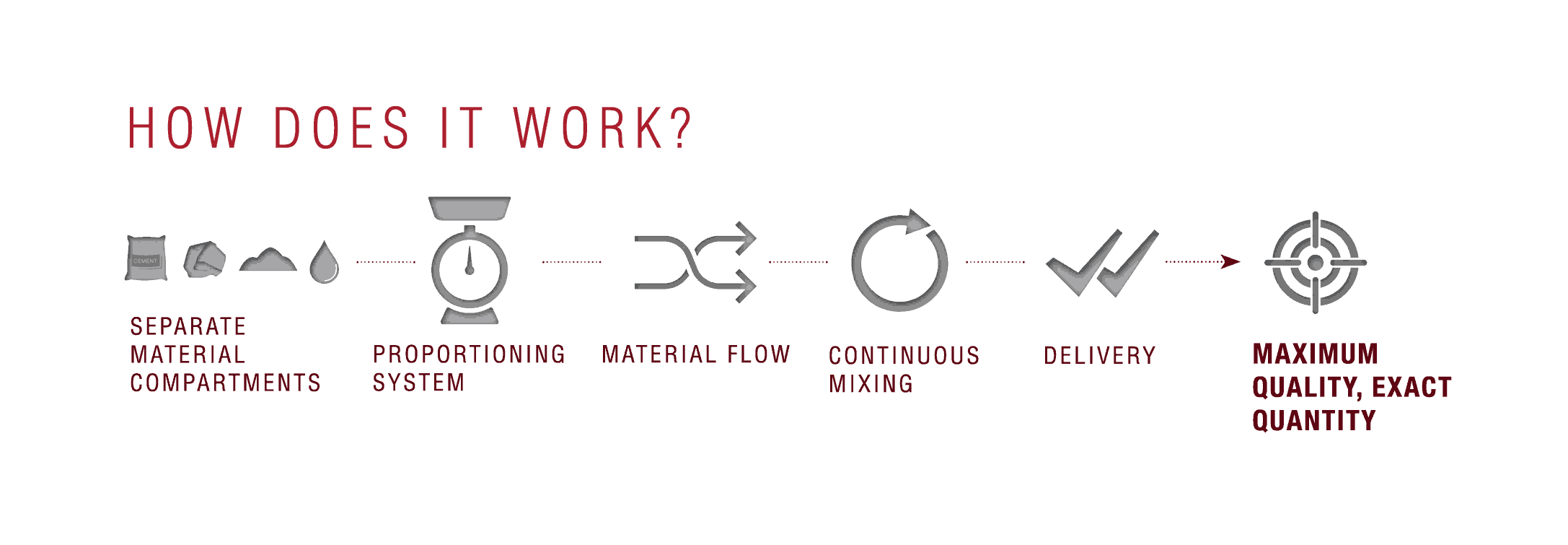

Each C Series mixer comes equipped with a state-of-the-art electronic control panel. The panel allows an operator in the field to track when a unit was in operation, how much concrete was poured, and the admixture used for each job. The information displays on a digital readout and also shows the exact use rate of aggregate, sand, water, and cement.

The C Series is the first volumetric concrete mixer to integrate with ACCU-POUR(TM). This suite of productivity solutions aims to help concrete producers expand and profitably grow their business. Job information is available with a few clicks for dispatchers while collected job data syncs between the mixer and office.

Every Cemen Tech solution comes with a Performance Guarantee. We stand by our products, customers and support our equipment better than anyone else in the industry.

BENEFITS

- Less cost and better quality than traditional drum mixing – accurate costs, precise mixtures and more uptime

- No “hot loads” or limited distance to jobs – separate materials storage on mobile unit ensures a fresh mix for maximum strength concrete on each job

- More time efficient – jobs can be done on-demand when your crew is ready for concrete, no need to go back to the plant to change applications or mixtures between jobs

- Consistently produce the exact mix design each and every time

- Less maintenance, on-site training and ongoing education from Cemen Tech team

- Eco friendly – less waste, less water, less carbon

FEATURES

- State-of-the-art electronic control panel

- Exclusive dual auger cement metering system

- Rack-and-pinion industrial grade aggregate gates

- Baffled poly water tank

- Replaceable Ni-Hard wear blades

- 2-ply aggregate belt with vanner edge

- Automated washout and stow